A Guide To Choosing Oak Flooring

When we deliver oak flooring, we like to use our own transport whenever possible. This way we get to see our customers in person and discuss their project further.

Recently, Adrian set off to deliver some solid oak flooring to a customer. He arrived on site to find a lovely, traditional home in the countryside. On arrival, he was greeted by the husband and wife owners, who were eager to see their new oak flooring. Whilst chatting away, the customers began to explain how the new flooring was to replace an existing oak floor they had purchased only a few years ago.

"What?!?" Adrian exclaimed. "An oak floor should last a lifetime, why are you replacing so soon?".

The customers then revealed their previous "oak flooring".

They described how they had hated their floor from the start and how they had been sold something in stark contrast to what they had received.

We thought this was a disgrace.

With this in mind, we have produced this guide to show you what you should be looking out for when purchasing oak flooring.

(![]() To download a printable pdf version of this guide, click here)

To download a printable pdf version of this guide, click here)

Summary

- Country Of Origin

- Moisture Content

- Length Of Board

- Width Of Board

- Thickness Of Board

- Surface Of The Board

- Finish Of The Board

Country Of Origin

Where the oak flooring board is sourced and produced is one the key aspects when purchasing oak flooring.

Oak flooring is available from around the world with Europe, American and China being the main exporters. Where the oak is sourced can be a factor in the overall quality of the oak board as well as influence how the board looks from above.

One of the most frequent questions we are asked is what is the difference between American and European oak?

American oak is available as red oak and white oak and is mainly sourced from North America.

European oak is sourced from European countries such as France, Germany and England.

American oak will typically have a much larger grain and larger growth rings than European oak. American oak flooring boards are typically much lighter and have more colour variation due to the number of different variations of American oak.

In our experience, European oak offers much better stability and better overall quality than American oak.

Moisture Content

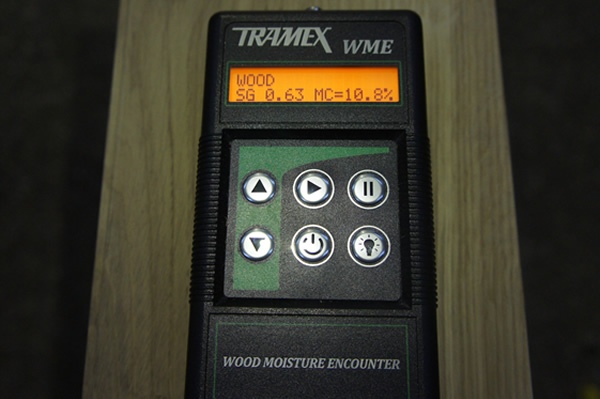

The moisture content of oak flooring is a factor that is not immediately obvious, yet very important nonetheless.

Moisture content tends to vary dependent on source. Boards dried down to lower than 8% (often the case with vacuum kiln-dried American oak) can often be in issue in the UK. When these boards are unwrapped from their airtight packaging, they will quickly swell in Britain's damp air with the danger that they may warp.

We recommend boards which are between 8 and 12% moisture content.

Length Of Board

Although oak flooring may be advertised as long lengths, it is important that you make a note of the minimum lengths.

Small pieces will often be unusable or look unsightly in your floor.

Long lengths on the other hand exude quality, like an oak floor should.

In the images below you can see some of the flooring taken from our customers home against some of our very own unfinished oak flooring.

The short piece we were given was only 90cm long and there were even shorter pieces than this!

Compare this to our 20mm oak flooring where pieces are no shorter than 2 metres.

What To Avoid

Very short lengths

What To Look For

Longest lengths possible for a quality appearance.

Width Of Board

The width of your oak flooring board is the next point to consider.

Whilst widths are very much a case of personal preference, it is important that you have a number of options available to you.

Very small widths, such as the 85mm piece shown from our customer do not look like traditional oak flooring at all.

Bigger rooms often look better with wider boards of 200mm+.

Smaller rooms you would normally choose thinner boards 120-140mm.

Mid-range widths, such as 160mm/180mm can often look great in all.

What To Avoid

Narrow boards more suited to parquet.

What To Look For

Wider planks displaying all the character we love to see in a traditional oak board.

Thickness Of Board

The thickness of the board best suited for your project will depend on whether you choose solid or engineered oak flooring, and what your floor will be fitted onto.

When laying onto joists and where the flooring needs to be structural, we always recommend a thicker 20mm board. If you are laying onto an existing wooden sub-floor, thinner boards such as our 14mm solid oak flooring can be used.

Engineered oak flooring is designed for those areas where a solid oak floor is simply not suitable or where the floor is required to be as stable as possible.

With engineered oak flooring, there are a number of factors to consider regarding its construction.

The thickness of the uppermost wear layer is the first point.

A thick wear layer is important to ensure the longevity of the engineered board - the thicker it is, the more often it can be re-sanded.

The ply-board beneath the wear layer provides the stability - the more ply layers, the more stable the board.

Our engineered oak flooring boards consist of 14mm of Siberian birch ply with a 6mm solid oak wear layer.

Although thinner engineered oak boards are available, we always recommend fitting the thickest board you can for your situation.

Surface Of The Board

The majority of oak flooring on the market is supplied with a flat surface and this is our preference when supplying unfinished solid oak flooring.

Some oak flooring is supplied with an artificially textured surface to simulate ageing or wear.

As with width, the surface is very much a case of personal preference, however it is important to consider maintenance when opting for textured surfaces as they can be harder to keep clean and repair.

Finish Of The Board

The final point to consider is the finish of your oak flooring.

The majority of the oak flooring we supply is unfinished.

This leaves you with the option to wax, oil or varnish your floor however you see fit.

Some floors are supplied pre-finished.

This means the oak boards have already been finished prior to laying the boards.

Please be aware that some companies will sell “pre-finished” oak flooring that will require additional coats after laying your floor.

What To Avoid

Poor quality unnatural finish which is not very hard wearing

What To Look For

Hard wearing natural finishes

Finally

If you take into account the points made in this guide, you should have nothing to fear when choosing your new oak floor.

It's well worth taking your time to shop around and to view your future floor in person, rather than risking an internet purchase sight unseen.

An online deal may promise to offer cost savings at first, but as our customers discovered, this may come back to haunt you later on...

Add a comment